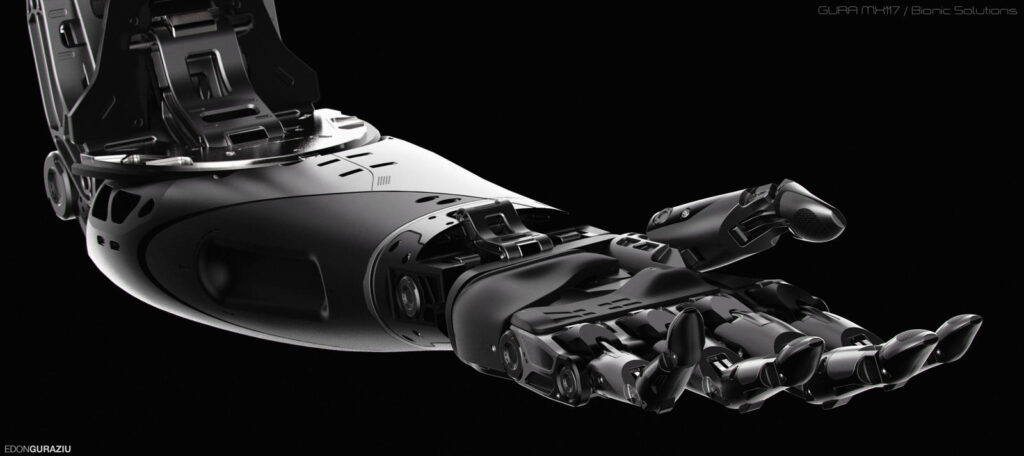

Robotic hand prostetic

Around March 2025, I started working on my first prosthetic design. It felt like the perfect overlap of my interests: biology, technology, and making a positive impact on the world.

The design began with three concepts:

- 3D Printable HRI Hand Variant

Based on the open-source HRI hand project—which uses kinematics and a well-studied joint structure to replicate finger movements—I created a fully printable version. Instead of bolts or pins, my model uses cone-shaped printable hinges, allowing each finger to be printed as a single piece. - String-Driven Mechanism

A custom design using string to control the hand’s movements. Two channels run through the hand, forming a loop for the string, which is connected to a servo motor. Rotating the motor turns a pulley, either bending the fingers or pulling them straight again. - Spring-Enhanced Version

An improved version of the second concept that adds a spring to the system. When the string is pulled, the fingers bend and the spring is tensioned. Releasing the tension makes the spring return the fingers to their outstretched position

Concept 1: 3d printable HRI hand.

Concept 3: Spring tensioned finger.

Refining the Final Concept

In the end, I decided to move forward with concept 3. It showed the best performance and avoided the major flaws of the other two.

Concept 1 had issues with finger strength—the printed hinges would pop out under pressure. Concept 2 struggled with the amount of string tension needed to move the fingers, making them difficult to control smoothly.

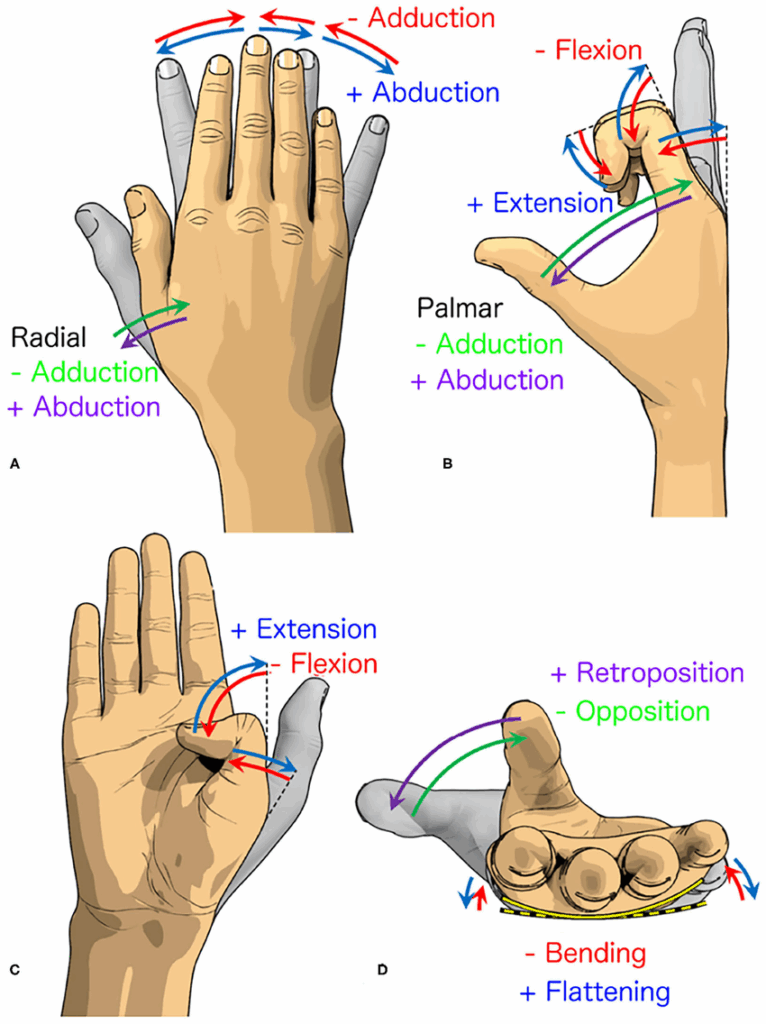

At this point, the fingers for version 3 are complete. I’m now working on optimizing the hand base to keep it lightweight while allowing room for improved dexterity. One key challenge is the thumb joint, which requires three degrees of freedom. To tackle this, I’ve been studying the actual joint in the human body and simplifying the mechanism to use a maximum of three motors.